Formulation and Comparison of Experimental based Mathematical Model with Artificial Neural Network Simulation on Surface Roughness with Burnished Spherical Surface Tool on Aluminum Alloy6351

Main Article Content

Abstract

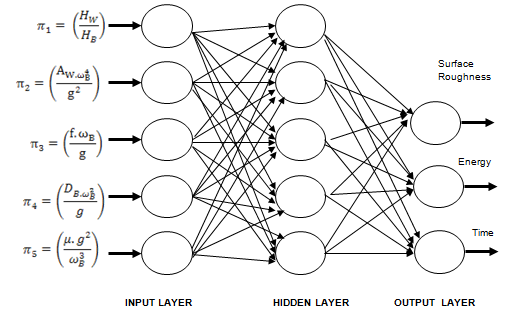

This paper deals with the effect of burnishing process on the Aluminum Alloy material 6351(HE 15) using Lathe. Surface roughness generated after the turning operation was used to ball burnishing. The surface roughness pattern which was further used to simulate ball burnishing process using ANN. Improvement in the surface roughness values achieved for tool steel after ball burnishing process was 98.2429%.

Article Details

References

Hassan Adel Mahmood. (1997) ‘The effects of ball- and roller-burnishing on the surface roughness and hardness of some non-ferrous metals’, Journal of Materials Processing Technology, Vol. 72, pp. 385–391.

Hassan, A.M., Al-Jalil, H.F., and Ebied, A.A. (1998) ‘Burnishing force and number of ball passes for the optimum surface finish of brass components’, Journal of Materials Processing Technology, Vol. 83, pp. 176–179.

Mohammadpour, M., Razfar, M.R., and Jalili Saffar, R. (2010) ‘Numerical investigating the effect of machining parameters on residual stresses in orthogonal cutting’, Simulation Modelling Practice and Theory, Vol. 18, pp. 378–389.

Partchapol Sartkulvanich. (2007) ‘Determination of material properties for use in FEM simulations of machining and roller burnishing’, PhD Dissertation, School of The Ohio State University, Ohio.

Yen Yung-Chang. (2004) ‘Modelling of metal cutting and ball burnishing predication of tool wear and surface properties’, PhD Dissertation, School oThe Ohio State University, Ohio.

Ravi Butola, Dr. Qasim Murtaza, Jitendra Kumar, “Design and Fabrication of Multi Ball Burnishing for Post Machining Finishing Process”, Indian Journal of Applied Research,Vol.3/6, P.P. [202-204],2013.

P. R. Prabhu, S. M. Kulkarni, S. S. Sharma, “Experimental Investigations of Parameters Influence on Surface Roughness in Deep Cold Rolling of AISI 4140 Steel”, International Journal of Research in Engineering and Technology ,Vol.1/3 ,P.P.[159-163], 2012.

Modak, J. P. & Bapat, A. R., “Formulation of Generalised Experimental Model for a Manually Driven Flywheel Motor and its Optimization”, Applied Ergonomics, U.K., Vol. 25, No. 2, pp 119-122, 1994.

P. R. Prabhu, S. M. Kulkarni, S. S. Sharma , “Influence of deep cold rolling and low plasticity burnishing on surface hardness and surface roughness of AISI 4140 steel”, World Academy of Science, Engineering and Technology ,Vol.72, P.P.[619-624], 2010.

Ugur Esme, “Use of Grey Based Taguchi Method In Ball Burnishing Process for The Optimization of Surface Roughness And Microhardness of AA7075 Aluminum Alloy”, Materials and Technology, Vol. 44/3 , P.P.[129–135],2010.

Stoic, I. Lackovic, Kopac, I. Samardzic , D. Kozak, “An investigation of machining efficiency of internal roller burnishing”, Journal of Achievements in Materials and Manufacturing Engineering ,Vol. 40/2, P.P.[1-6], 2010.

J. Naga Malleswara Rao, A. Chenna Kesava Reddy , P.V. Rama Rao, “Design and fabrication of new type of dynamometer to measure radial component of cutting force and experimental investigation of optimum burnishing force in roller burnishing process”, Indian Journal of Science and Technology ,Vol.3/7, P.P. [737-742], 2010.

F. Gharbi, S. Sghaier, K.J. Al-Fadhalah, T. Benameur, “Effect of Ball Burnishing Process on the Surface Quality and Microstructure Properties of AISI 1010 Steel Plate”, Journal of Materials Engineering and performance, P.P.[1-6],2010.

Mieczyslaw Korzynskia, Andrzej Pacanab, “Centreless burnishing and influence of its parameters on machining effects”, Journal of Materials Processing Technology, Vol. 210, P.P.[1217–1223],2010.

Liu Jian-ying, Yang Zhao-jun, “Reliability Assessment of Burnishing Processing of Aluminum Alloy”, IEEE. , Vol. 7/09, P.P. [315-318], 2009.

T. A. El-Taweel & M. H. El-Axir, “Analysis and optimization of the ball burnishing process through the Taguchi technique”, International Journal of Advance Manufacturing Technology, Vol.41, P.P. [301-310], 2009.

Basu S.K., Mukherjee S.N., Mishra R., Fundamentals Of Tool Engineering Design, Fifth Edition, Oxford and IBH Publishing Co. Pvt. Ltd., P.P.: - [44-45],[47],[48],[50],[22], 1993.

Basu S.K.,Pal D.K , Design of Machine Tools, Fourth Edition, Oxford and IBH Publishing Co. Pvt. Ltd., P.P.:- [47],[37],1990.

ASTME National Technical Publication Committee, Tool Engineer’s Handbook,, Second Edition, Mc-Graw Hill Book Company,Inc,New York, P.P.: - [26(36-37)], 1959.

Central Machine Tool Institute, Banglore, Machine Tool Design Handbook, Fifth Edition, Tata Mc-Graw –Hill Publishing Co. Ltd., New York, P.P.: - [639], [666], [638], [639], 1988.

Hilbert Schenck Junier, Theory of Engineering Experimentation, Mc Graw Hill, New York.