Exploratory Data Analysis for Textile Defect Detection

Main Article Content

Abstract

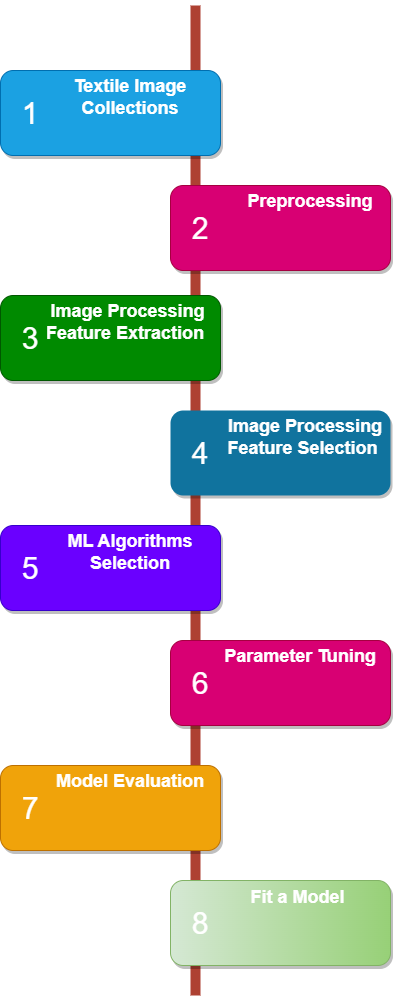

The capacity to recognize anomalies in real-world visual data is essential for many computer vision uses. New approaches and ideas in unsupervised defective garments identification require data for training and evaluation. Understanding the constraints of the currently employed approach of human inspection is crucial for improving clothing quality. Uses for digital image processing in the textile sector are suggested. This method proposes a novel quantitative measuring strategy by fusing digital image processing with the Lab view platform. As this study progresses, it becomes clear that the FLDA yields the best results, with 95% accuracy, while the Hoeffiding Tree yields the lowest results, with 60% accuracy. When compared to other models, the FLDA's precision of 0.96 is the best you'll find, while the Hoeffiding Tree's is the lowest at 0.62. The FLDA provides the best result, with a recall value of 0.95, while the Hoeffiding Tree shows the lowest result, with a recall value of 0.60. The FLDA yields the best results (0.90 kappa value), whereas the Hoeffiding Tree yields the worst (0.20 kappa value).The FLDA exhibits the best results, with an F-Measure value of 0.95, while the Hoeffiding Tree displays the lowest results, with an F-Measure value of 0.58. The FLDA provides the best results, with an MCC value of 0.91, while the Hoeffiding Tree displays the worst results, with an MCC value of 0.22. The FLDA yields the best results (0.98 ROC value), whereas the Decision Table produces the worst results (0.69 ROC value). The best prediction accuracy is shown by the FLDA, at 0.98 of the PRC value, while the worst is shown by the Decision Table, at 0.67. The MAE is lowest (0.07) for the FLDA and highest (0.39) for the Hoeffiding Tree. The MAE deviation of the Bayes Net is 0.19. The best result is shown by the FLDA, with an RMSE of 0.22, while the largest RMSE deviation is found in the Hoeffiding Tree, at 0.62. The RMSEdeviation for Bayes Net is 0.41. The finest RAE is shown by the FLDA, at 13.39%, while the largest RAE deviation is 78.28% for the Hoeffiding Tree. The Bayes Net explains 38.74% of the variation in RAE. The best result is shown by the FLDA, with an RRSE of 44.36%; the largest RRSE variation is shown by the Hoeffiding Tree, with 123.99%. When compared to other models, the IBK's preparation time of 0 seconds is by far the shortest. While the Bayes Net completes its task in 0.03 seconds, FLDA can take up to 0.17 seconds. The FLDA model is found to have superior performance in this study.

Article Details

References

Paul Bergmann, Michael Fauser, David Sattlegger, Carsten Steger. MVTec AD - A Comprehensive Real-World Dataset for Unsupervised Anomaly Detection; in: IEEE Conference on Computer Vision and Pattern Recognition (CVPR), June 2019.

Jacintha and S. karthikeyan, “A survey on various fabric defect detection methods,” in 2019 International Conference on Communication and Signal Processing (ICCSP), April 2019, pp. 0801–0805.

R. Divyadevi and B. V. Kumar, “Survey of automated fabric inspection in textile industries,” in 2019 International Conference on Computer Communication and Informatics (ICCCI), Jan 2019, pp. 1–4.

X. Wang, N. D. Georganas, and E. M. Petriu, “Automatic woven fabric structure identification by using principal component analysis and fuzzy clustering,” in 2010 IEEE Instrumentation Measurement Technology Conference Proceedings, May 2010, pp. 590–595.

O. Kaynar, Y. E. Is¸ik, Y. Gormez, and F. Demirkoparan, “Fabric defect detection with lbp-glmc,” in 2017 International Artificial Intelligence and Data Processing Symposium (IDAP), Sep. 2017, pp. 1–5.

C. Li, G. Gao, Z. Liu, M. Yu, and D. Huang, “Fabric defect detection based on biological vision modeling,” IEEE Access, vol. 6, pp. 27 659– 27 670, 2018.

L. Jia, J. Zhang, S. Chen, and Z. Hou, “Fabric defect inspection based on lattice segmentation and lattice templates,” J. Franklin Institute, vol. 355, no. 15, pp. 7764–7798, 2018.

H. Tian and F. Li, “Autoencoder-based fabric defect detection with crosspatch similarity,” in 2019 16th International Conference on Machine Vision Applications (MVA), May 2019, pp. 1–6.

X. Wang, G. Wu, and Y. Zhong, “Fabric identification using convolutional neural network,” in International Conference on Artificial Intelligence on Textile and Apparel. Springer, 2018, pp. 93–100.

T. Grubinger, G. Chasparis, and T. Natschlager, “Generalized online transfer learning for climate control in residential buildings,” Energy and Buildings, vol. 139, pp. 63–71, 01 2017.

C. Mazo, J. Bernal, M. Trujillo, and E. Alegre, “Transfer learning for classification of cardiovascular tissues in histological images,” Computer Methods and Programs in Biomedicine, vol. 165, 08 2018.

H. K. Suh, J. IJsselmuiden, J. W. Hofstee, and E. J. van Henten, “Transfer learning for the classification of sugar beet and volunteer potato under field conditions,” Biosystems Engineering, vol. 174, pp. 50 – 65, 2018. [Online].Available:http://www.sciencedirect.com/science/article/pii/S1537511016308777

Q. Lin, J. Hong, Z. Liu, B. Li, and J. Wang, “Investigation into the topology optimization for conductive heat transfer based on deep learning approach,” International Communications in Heat and Mass Transfer, vol. 97, pp. 103 – 109, 2018. [Online].

Q. Wang, P. Du, J. Yang, G. Wang, J. Lei, and C. Hou, “Transferred deep learning based waveform recognition for cognitive passive radar,” Signal Processing, vol. 155, pp. 259 – 267, 2019. [Online]. Available: http://www.sciencedirect.com/science/article/pii/S0165168418303256

X. Li, H. Liu, P. Lv, and L. Liu, “Theoretical model for the motion of a ring spinning traveler,” Journal of the Textile Institute, vol. 112, no. 3, pp. 1–11, 2020.

Yahya Ghufran Khidhir, Ameer Hussein Morad. (2023). Real-Time End-to-End Self-Driving Car Navigation. International Journal of Intelligent Systems and Applications in Engineering, 11(2s), 366–372. Retrieved from https://ijisae.org/index.php/IJISAE/article/view/2732

E. Owlia and S. A. Mirjalili, “The effect of launcher parameters on the projectile velocity in laboratory electromagnetic weft insertion system,” Journal of the Textile Institute, vol. 112, no. 8, pp. 1–8, 2020.

H. S. Khaddam and G. G. Ahmad, “A method to evaluate the diameter of carded cotton yarn using image processing and artificial neural networks,” Journal of the Textile Institute, no. 3, pp. 1–10, 2021.

Y. Shu, B. Li, D. Zuo, J. Zhang, and H. Gan, “Surface defect detection and recognition method for multi-scale commutator based on deep transfer learning,” Arabian Journal for Science and Engineering, no. 7, pp. 1–12, 2021.

W. Amir and A. Ahmed, “Applied vision about green marketing for trademark in the field of textile design and finishing,” Journal of Design Sciences and Applied Arts, vol. 2, no. 1, pp. 85–99, 2021

K. Parvesh, C. Tharun, and M. Prakash, “Apparel recommendation engine using inverse document frequency and weighted average Word2vec,” Journal of Cognitive Human-Computer Interaction, vol. 1, no. 2, pp. 46–56, 2021.

J. Li, D. Chen, N. Yu, Z. Zhao, and Z. Lv, “Emotion recognition of Chinese paintings at the thirteenth national exhibition of fines arts in China based on advanced affective computing,” Frontiers in Psychology, vol. 12, Article ID 741665, 2021.

A. Noor, M. A. Saeed, T. Ullah, Z. Uddin, and R. Khan, “A review of artificial intelligence applications in apparel industry,” Journal of the Textile Institute, vol. 113, no. 3, pp. 1–10, 2021.

F. Saad, A. Baffoun, B. Mahltig, and M. Hamdaoui, “Polyester fabric with fluorescent properties using microwave technology for anti-counterfeiting applications,” Journal of Fluorescence, vol. 32, no. 1, pp. 327–345, 2021.

B. Sharma, N. Kumari, S. Mathur, and V. Sharma, “A systematic review on iron-based nanoparticle-mediated clean-up of textile dyes: challenges and prospects of scale-up technologies,” Environmental Science and Pollution Research, vol. 29, no. 1, pp. 312–331, 2021.

P. Secim-Karakaya, P. Saglam-Metiner, and O. Yesil-Celiktas, “Antimicrobial and wound healing properties of cotton fabrics functionalized with oil in water emulsions containingpinus brutiabark extract and pycnogenol for biomedical applications,” Cytotechnology, vol. 73, no. 3, pp. 423–431, 2021.

Wang Wei, Natural Language Processing Techniques for Sentiment Analysis in Social Media , Machine Learning Applications Conference Proceedings, Vol 1 2021.

M. Rahman, N. Cicek, and K. Chakma, “The optimum parameters for fibre yield (%) and characterization oftypha latifolia l.fibres for textile applications,” Fibers and Polymers, vol. 22, no. 6, pp. 1543–1555, 2021.

J Thambu Gladstan , Dr.E.Mohan. “Object Recognition Based on Wave Atom Transform,” Research Journal of Applied Sciences, Engineering and Technology – Volume 8 ,issue 13, 1613-1617, 2014, ISSN: 2040-7459; e-ISSN: 2040-7467

I. Z. Ansari and M. M. Mehadi, “An aesthetic approach of seamless garments: a review,” Journal of Textile Engineering, vol. 1, no. 1, pp. 66–72, 2021.

S. Wan, Y. Xia, L. Qi, Y. H. Yang, and M. Atiquzzaman, “Automated colorization of a grayscale image with seed points propagation,” IEEE Transactions on Multimedia, vol. 22, no. 7, pp. 1756–1768, 2020.

Dr. Antino Marelino. (2014). Customer Satisfaction Analysis based on Customer Relationship Management. International Journal of New Practices in Management and Engineering, 3(01), 07 - 12. Retrieved from http://ijnpme.org/index.php/IJNPME/article/view/26

C. T. O’Neill, T. Proietti, K. Nuckols et al., “Inflatable soft wearable robot for reducing therapist fatigue during upper extremity rehabilitation in severe stroke,” IEEE Robotics and Automation Letters, vol. 5, no. 3, pp. 3899–3906, 2020.

M. Leone, “Digital cosmetics: a semiotic study on the Chinese and global meanings of the face in image-processing apps,” Chinese Semiotic Studies, vol. 16, no. 4, pp. 551–580, 2020.

T. D. P. Caldas, K. S. Augusto, J. C. Á. Iglesias, S. Paciornik, and A. L. A. Domingues, “Analysis of cracks and coating in iron ore pellets by digital image processing,” REM-International Engineering Journal, vol. 73, no. 3, pp. 345–352, 2020.

E.Mohan,Dr.C.Puttamadappa et.al ““Facial Tracking in Video Using Artificial Neural Networks”, International Journal of Soft Computing 3(4):271-276, 2008.

V. V. Kibitkin and A. I. Solodushkin, “Increasing measuring area of deformed solid by digital image correlation,” Russian Physics Journal, vol. 64, no. 4, pp. 599–604, 2021.

B. Jia and W. Zhang, “Application of digital image processing technology in online education under covid-19 epidemic,” Journal of Intelligent and Fuzzy Systems, no. 2, pp. 1–7, 2021.

S. Ahmad and S. Miskon, “A conceptual model of business intelligence system adoption for the textile and apparel industry in Pakistan,” Mehran University Research Journal of Engineering and Technology, vol. 40, no. 2, pp. 251–264, 2021.

A. R. W. Sait, I. Pustokhina, and M. Ilayaraja, “Modeling of multiple share creation with optimal signcryption technique for digital image security,” Journal of Intelligent Systems and Internet of Things, vol. 0, no. 1, pp. 26–36, 2019.

M. Terzi, I. Kursun Unver, M. Cinar, and O. Ozdemir, “Digital image processing (dip) application on the evaluation of iron-rich heavy mineral concentrates produced from river sand using a sequential mineral processing approach,” Physicochemical Problems of Mineral Processing, vol. 57, no. 3, pp. 21–35, 2021.

C. Liu, “An enhanced cascaded beamformer based on overlapped subarrays,” Signal, Image and Video Processing, vol. 16, no. 4, pp. 905–910, 2021.

Rodriguez, L., Rodríguez, D., Martinez, J., Perez, A., & Ólafur, J. Leveraging Machine Learning for Adaptive Learning Systems in Engineering Education. Kuwait Journal of Machine Learning, 1(1). Retrieved from http://kuwaitjournals.com/index.php/kjml/article/view/103

S. Chakraborty and M. C. Biswas, “Impact of covid-19 on the textile, apparel and fashion manufacturing industry supply chain: case study on a ready-made garment manufacturing industry,” SSRN Electronic Journal, vol. 3, no. 2, pp. 1–22, 2020