Energy-Efficient Flexible Flow Shop Scheduling With Due Date and Total Flow Time

Main Article Content

Abstract

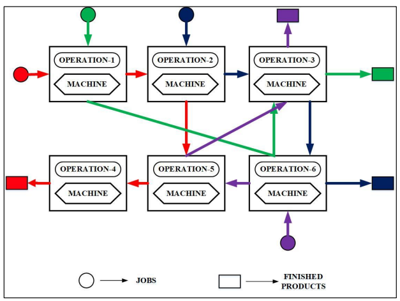

One of the most significant optimization issues facing a manufacturing company is the flexible flow shop scheduling problem (FFSS). However, FFSS with uncertainty and energy-related elements has received little investigation. Additionally, in order to reduce overall waiting times and earliness/tardiness issues, the topic of flexible flow shop scheduling with shared due dates is researched. Using transmission line loadings and bus voltage magnitude variations, an unique severity function is formulated in this research. Optimize total energy consumption, total agreement index, and make span all at once. Many different meta-heuristics have been presented in the past to find near-optimal answers in an acceptable amount of computation time. To explore the potential for energy saving in shop floor management, a multi-level optimization technique for flexible flow shop scheduling and integrates power models for individual machines with cutting parameters optimisation into energy-efficient scheduling issues is proposed. However, it can be difficult and time-consuming to fine-tune algorithm-specific parameters for solving FFSP.

Article Details

References

Gong, G., Chiong, R., Deng, Q., Han, W., Zhang, L., Lin, W., & Li, K. (2020). Energy-efficient flexible flow shop scheduling with worker flexibility. Expert Systems with Applications, 141, 112902.

Feng, Y., Deb, S., Wang, G. G., &Alavi, A. H. (2021). Monarch butterfly optimization: a comprehensive review. Expert Systems with Applications, 168, 114418.

Zhao, F., Qin, S., Zhang, Y., Ma, W., Zhang, C., & Song, H. (2019). A hybrid biogeography-based optimization with variable neighborhood search mechanism for no-wait flow shop scheduling problem. Expert Systems with Applications, 126, 321-339.

Buddala, R., &Mahapatra, S. S. (2018). Improved teaching–learning-based and JAYA optimization algorithms for solving flexible flow shop scheduling problems. Journal of Industrial Engineering International, 14(3), 555-570.

Huang, R. H., Yu, S. C., & Chen, P. H. (2017). Energy-saving scheduling in a flexible flow shop using a hybrid genetic algorithm. Journal of Environmental Protection, 8(10), 1037-1056.

Rao, R. V., Rai, D. P., Ramkumar, J., &Balic, J. (2016). A new multi-objective Jaya algorithm for optimization of modern machining processes. Advances in Production Engineering & Management, 11(4).

Rezaeian, J., Derakhshan, N., Mahdavi, I., & AlizadehForoutan, R. (2021). Due dateassignment and JIT scheduling problem in blocking hybrid flow shop robotic cells withmultiple robots and batch delivery cost?. International journal of industrialmathematics, 13(2), 145-162.

Zheng, J., Wang, L.,; Wang, J. J. (2020). A cooperative coevolution algorithm formulti-objective fuzzy distributed hybrid flow shop. Knowledge-Based Systems, 194,105536.

Cai, J., Zhou, R.; Lei, D. (2020). Fuzzy distributed two-stage hybrid flow shopscheduling problem with setup time: collaborative variable search. Journal of Intelligent; Fuzzy Systems, 38(3), 3189-3199.

Lin, Y. K.; Huang, D. H. (2020). Reliability analysis for a hybrid flow shop with duedate consideration. Reliability Engineering; System Safety, 199, 105905.

Schulz, S., Buscher, U.; Shen, L. (2020). Multi-objective hybrid flow shop schedulingwith variable discrete production speed levels and time-of-use energy prices. Journal ofBusiness Economics, 90(9), 1315-1343.

Chou FD (2013) Particle swarm optimization with cocktail decoding method for hybrid flow shop scheduling problems with multiprocessor tasks. Int J Prod Econ 141(1):137–145.

Cui Z, Gu X (2015) An improved discrete artificial bee colony algorithm to minimize the makespan on hybrid flow shop problems. Neurocomputing 148:248–259

Marichelvam MK, Geetha M (2016) Application of novel harmony search algorithm for solving hybrid flow shop scheduling problems to minimisemakespan. Int J IndSystEng 23(4):467–481

Marichelvam MK, Prabaharan T, Yang XS (2014) Improved cuckoo search algorithm for hybrid flow shop scheduling problems to minimize makespan. Appl Soft Comput 19:93–101

Mousavi SM, Zandieh M, Yazdani M (2013) A simulated annealing/local search to minimize the makespan and total tardiness on a hybrid flowshop. Int J AdvManufTechnol 64(1–4):369–388

Rao R (2016) Jaya: A simple and new optimization algorithm for solving constrained and unconstrained optimization problems. Int J IndEngComput 7(1):19–34

Singh MR, Mahapatra SS (2012) A swarm optimization approach for flexible flow shop scheduling with multiprocessor tasks. Int J Adv Manuf. Technol 62(1–4):267–277

Zhang, R., &Chiong. R. (2016). Solving the energy-efficient job shop schedulingproblem: A multi-objective genetic algorithm with enhanced local search forminimizing the total weighted tardiness and total energy consumption. Journalof Cleaner Production, 112, 3361-3375.

Zhang, Z. W., Wu, L. H., Peng, T., &Jia, S. (2019). An improved scheduling approachfor minimizing total energy consumption and makespan in a flexible job shopenvironment. Sustainability, 11. 1-21.

Zhao, F. Q, Qin, S., Yang, G. Q., Ma, W. M. Zhang, C., & Song, H. B. (2019). A factorial based particle swarm optimization with a population adaptation mechanism for the no-wait flow shop scheduling problem with the makespan objective. ExpertSystems with Applications, 126, 41-53.

Zhao, F. Q. Qin, S. Zhang, Y. Ma, W. M. Zhang, C. & Song, H. B. (2019). A hy- brid biogeography-based optimization with variable neighborhood search mech- anism for no-wait flow shop scheduling problem. Expert Systems with Applica tions, 126, 321-339.

Wu, X., Shen, X., & Cui, Q. (2018). Multi-objective flexible flow shop scheduling problem considering variable processing time due to renewable energy. Sustain- ability, 10, 841.

Xu, Y. Wang, L. Wang, S. Y. & Liu, M. (2014). An effective hybrid immune algo- rithm for solving the distributed permutation flow-shop scheduling problem. Engineering Optimization, 46, 1269-1283.

Yin, L. Li, X. Gao, L. Lu, C., & Zhang, Z. (2017). Energy-efficient job shop scheduling problem with variable spindle speed using a novel multi-objective algorithm. Advances in Mechanical Engineering 9, 1-21.

Yuan, Y. &Xu, H. (2015). Multiobjective flexible job shop scheduling using memetic algorithms.IEEE Transactions on Automation Science and Engineering. 12, 336-353.

Tirkolaee, E. B., Goli, A.; Weber, G. W. (2020). Fuzzy mathematical programmingand self-adaptive artificial fish swarm algorithm for just-in-time energy-aware flow shopscheduling problem with outsourcing option. IEEE transactions on fuzzy systems, 28(11),2772-2783.

Jiang, W.; Wu, L. (2021). Flow shop optimization of hybrid make-to-order and make-to-stock in precast concrete component production. Journal of Cleaner Production, 297,126708.