New Biomedical Applications Approach using Shape Memory Polymers for Muscles Rehabilitation and the Accompanying Wounds after Severe Bone Fractures

Main Article Content

Abstract

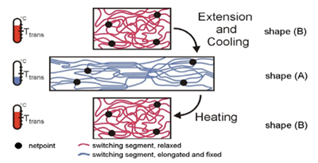

This article introduces a new approach for modern applications of medical devices using shape memory polymers to aid in the rehabilitation of muscles and injuries attached to severe fractures. The group of heaters connected with the splint controls the temperature and humidity inside the affected area. Microcontrollers were attached to the polymer plate in order to directly control the required parameters and changes in addition to giving direct commands to the connected sensors. Because of the property of changing the outer shape of the polymer after being exposed to a certain temperature and returning to the normal shape after the removal of the external influence, the designed polymer plate applies light intermittent pressure on the wound area, muscles, and surrounding tissues, which helps to speed up the rehabilitation of these muscles, especially after She suffered from stiffness due to lack of movement during the period of treatment.

Article Details

References

Lendlein, A., & Behl, M. (2008). “Shape-memory polymers for biomedical applications”. CIMTEC Proceedings of the 3rd International Conference on Smart Materials, Structures and Systems - Smart Materials and Micro/Nanosystems, 54, 96–102.. https://doi.org/10.4028/www.scientific.net/AST.54.96.

M. Kaliva, M. Chatzinikolaidou and M. Vamvakak. (2008). “Intelligent Materials”. Royal Society of Chemistry, pp. P001–P004.. https://doi.org/10.1039/9781847558008-fp001.

Behl, M., & Lendlein, A. (2007). “Actively moving polymers”. Soft Matter Vol. 3, Issue 1, pp. 58–67. https://doi.org/10.1039/b610611k.

Behl, M., & Lendlein, A. (2007). “Shape-memory polymers”. Materialstoday, vol10, issue4, p.p 20-28.. https://doi.org/10.1016/S1369-7021(07)70047-0.

Feninat, F. el, Laroche, G., Fiset, M., & Mantovani, D. (2002). “Shape Memory Materials for Biomedical Applications”, Advanced Engineering materials. vol.4, issue3, p.p 91-104. https://doi.org/10.1002/1527-2648(200203)4:3<91::AID-ADEM91>3.0.CO;2-B.

Zotzmann, J., Ziegler, H. J., Behl, M., Zierke, M., Radke, W., & Lendlein, A. (2011). “Upscaling the synthesis of biodegradable multiblock copolymers capable of a shape-memory effect”. Journal of Materials Science: Materials in Medicine, 22(10), p.p 2147–2154. https://doi.org/10.1007/s10856-011-4404-6.

Andreas Lendlein, and Steffen Kelch. (2005). “Shape-Memory Effect”. Encyclopedia of materials: scince and technology. 10.1016/B0-08-043152-6/02033-7

Safranski, D. L., & Griffis, J. C. (2015). “Mechanical properties of shape-memory polymers for biomedical applications”. Shape Memory Polymers for Biomedical Applications. pp. 9–33. Elsevier Ltd. https://doi.org/10.1016/B978-0-85709-698-2.00002-7.

Dere, G. (2021). “Chapter Biomedical Applications with Using Embedded Systems”. http://dx.doi.org/10.5772/intechopen.96070

Al-Sawaff, Z. H., Rashid, Z. M., Yahya, Y. Z., & Kandemirli, F. (2020). “Electromagnetic field smart splint for bone fixing and rehabitation using niti shape memory alloy”. NeuroQuantology, 18(3), p.p 37–44. https://doi.org/10.14704/nq.2020.18.3.NQ20148.

Al-Sawaff, Z. H., Rashid, Z. M., Al-Okby, M. F. R., & Kandemirli, F. (2022 ). “A microcontroller based microfluidic biochip for calcium percentage detection in blood”. Indonesian Journal of Electrical Engineering and Computer Science, 6(1), 135–142. https://doi.org/10.11591/ijeecs.v26.i1.pp135-142.

Burgo, J. M. D. A. del, Haro, F. B., D’amato, R., & Méndez, J. A. J. (2020). “Development of a smart splint to monitor different parameters during the treatment process”. Sensors, 20(15), p.p 1–14. https://doi.org/10.3390/S20154207.

de Agustín Del Burgo, J. M., Blaya Haro, F., D’Amato, R., & Juanes Méndez, J. A. (2020). “Smart splint for diagnosis during initial stage of treatment”. ACM International Conference Proceeding Series, 458–466. https://doi.org/10.1145/3434780.3436610.

Li, K., Zhuang, S., Liu, J., Guo, A., Wang, A., Lu, J., & Xue, F. (2021). “Design of an intelligent medical splint with 3D printing and pressure detection”. 2021 IEEE 2nd International Conference on Big Data, Artificial Intelligence and Internet of Things Engineering, ICBAIE, 655–658. https://doi.org/10.1109/ICBAIE52039.2021.9389935.

Dao, T. D., Ha, N. S., Goo, N. S., & Yu, W. R. "(2018). Design, fabrication, and bending test of shape memory polymer composite hinges for space deployable structures". Journal of Intelligent Material Systems and Structures, 29(8), p.p 1560–1574. https://doi.org/10.1177/1045389X17742728.

Narendra Kumar, U., Kratz, K., Behl, M., & Lendlein, A. (2012). “Shape-memory properties of magnetically active triple-shape nanocomposites based on a grafted polymer network with two crystallizable switching segments”. Express Polymer Letters, 6(1), p.p 26–40.. https://doi.org/10.3144/expresspolymlett.2012.4.

Huang, W. M., Lee, C. W., & Teo, H. P. (2006). “Thermomechanical behavior of a polyurethane shape memory polymer foam”. Journal of Intelligent Material Systems and Structures, 17(8–9), p.p 753–760. https://doi.org/10.1177/1045389X06055768.

Kunzelman, J., Chung, T., Mather, P. T., & Weder, C. (2008). “Shape memory polymers with built-in threshold temperature sensors”. Journal of Materials Chemistry, 18(10), p.p 1082–1086. https://doi.org/10.1039/b718445j.

Rottiers, W., van den Broeck, L., Chris Peeters, ing, & Peter Arras, ing. “Shape Memory Materials and their applications”. p.p 1-12. 2012. https://www.semanticscholar.org/paper/Shape-memory-materials-and-their-applications-Rottiers Broeck/c5507ddafc0d17133ab16c9b5a30d41ff84e6c07

Tobushi, H., Hashimoto, T., Hayashi, S., & Yamada, E. (1997). “Thermomechanical constitutive modeling in shape memory polymer of polyurethane series”. Journal of Intelligent Material Systems and Structures, vol. 8(8), p.p 711–718. https://doi.org/10.1177/1045389X9700800808.

Casati, R., Vedani, M., Tofail, S. A. M., Dikinson, C., & Tuissi, A. (2012). “On the preparation and characterization of thin NiTi shape memory alloy wires for MEMS”. Frattura Ed Integrita Strutturale, vol. 23, p.p 7–12. https://doi.org/10.3221/IGF-ESIS.23.01.

Mahmood, M. F., Jameel, H. F., & Hammed, M. A. N. (2022). “Measurement of an electroretinogram signal and display waves on graphical user interface by laboratory virtual instrument engineering workbench”. Indonesian Journal of Electrical Engineering and Computer Science, vol. 25(2), p.p 980–988. https://doi.org/10.11591/ijeecs.v25.i2.pp980-988.

Hashim, F. A., Farid, S. B. H., & Salih, E. M. S. “Surface Treatment of NiTi Shape Memory Alloys used in Dentistry”. International Journal of Current Engineering and Technology Vol. 5, Issue 6. http://inpressco.com/category/ijcet.

Yakubu, O., & Wereko, E. (2021). “Internet of things based vital signs monitoring system: A prototype validity test”. Indonesian Journal of Electrical Engineering and Computer Science, vol. 23(2), p.p 962–972. https://doi.org/10.11591/ijeecs.v23.i2.pp962-972.

Talebi, H., Golestanian, H., Zakerzadeh, M. R., & Homaei, H. (2014). “Thermoelectric Heat Transfer Modeling of Shape Memory Alloy Actuators”. The 22st Annual International Conference on Mechanical Engineering-ISME2014. p.p 1-6. 2014

Reed, Jr., J. L., Hemmelgarn, C. D., Pelley, B. M., & Havens, E. (2005). “Adaptive wing structures”. Industrial and Commercial Applications of Smart Structures Technologies. vol. 5762, issue 132. https://doi.org/10.1117/12.599922.

Bye, D. R., & Mcclure, P. D. (2007). “Design of a Morphing Vehicle”. 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 15th23 - 26 April, Honolulu, Hawaii.

Yu, K., Yin, W., Sun, S., Liu, Y., & Leng, J. (2009). “Design and analysis of morphing wing based on SMP composite”. Industrial and Commercial Applications of Smart Structures Technologies, 7290, 72900S. https://doi.org/10.1117/12.815712.

Yin, W., Fu, T., Liu, J., & Leng, J. (2009). “Structural shape sensing for variable camber wing using FBG sensors”. Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, 7292, 72921H. https://doi.org/10.1117/12.812484.

Michelle M. Keihl, Robert S. Bortolin, Brian Sanders, Shiv Joshi, Zeb Tidwell, (2005). "Mechanical properties of shape memory polymers for morphing aircraft applications," Proc. SPIE 5762, Smart Structures and Materials: Industrial and Commercial Applications of Smart Structures Technologies. https://doi.org/10.1117/12.600569.

Bear E., “Advanced polymers”. Scientific American J., Vol 225, No.4, 1986. Pp. 178-190.

Al Dahoud, A., Fezari Badji Mokhtar -, M., Sh, M., Al-Mimi, H., Al-Dahoud, A., Fezari, M., & Sh Daoud, M. (2020). “A Study on New Arduino NANO Board for WSN and IoT Applications”. International Journal of Advanced Science and Technology, 29(4), p.p 10223–10230. https://www.researchgate.net/publication/345055896.

Kamweru, P., Ochieng Robinson, O., Paul Kuria, K., & Mutava Gabriel, M. (2020). “Monitoring Temperature and Humidity using Arduino Nano and Module-DHT11 Sensor with Real Time DS3231 Data Logger and LCD Display”. International Journal of Engineering Research & Technology. vol.9(12). p.p 416-422. https://www.researchgate.net/publication/347950991.

Jon S. Wilson. (2005). “Sensor Technology Handbook”. Elsevier Inc. ISBN: 0-7506-7729-5..

Mamadou Wade, Moussa Gueye, Ousmane Sow, et al. (2018). “Development of a Solar Controller with MLI Control”. Circuits and Systems. vol. 9(2). https://doi.org/10.4236/cs.2018.92003.

Akilesh M, Shanmuga Sundaram R, Naveen Kumar V S, Shenbagapriya M, Praveen K. (2022). “IoT based Humidity and Temperature Monitoring System using Arduino Uno”. International journal of engineering research & technology (IJERT) ETEDM. Volume 10 – Issue 08. https://doi.org/10.17577/IJERTCONV10IS08033.

Ju, X., Nebel, J.-C., & Siebert, J. P. (2005). “3D thermography imaging standardization technique for inflammation diagnosis”. Infrared Components and Their Applications, no. 5640, 266. https://doi.org/10.1117/12.577055.

Hafeez, F., Sheikh, U. U., Khidrani, A., Bhayo, M. A., Abdallah Altbawi, S. M., & Jumani, T. A. (2021). “Distant temperature and humidity monitoring: Prediction and measurement”. Indonesian Journal of Electrical Engineering and Computer Science, 24(3), 1405–1413. https://doi.org/10.11591/ijeecs.v24.i3.pp1405-1413.

S. Zhao, M. Arnold, S. Ma, R. l. Abel, J. P. Cobb, U. Hansen, O. Boughton. (2018). “standardizing compression testing for measuring the stiffness of human bone”. BiOMAteRiAlS. vol. 7, No. 8.. https://doi:10.1302/2046-3758.78.BJR-2018-0025.R1.

LAWSON R. “Implications of surface temperatures in the diagnosis of breast cancer”. Canadian Medical Association journal, 75(4), 309–311. 1956.

Çetinkaya, M. A., & Demirutku, A. (2012). “Thermography in the assessment of equine lameness”. Turkish Journal of Veterinary and Animal Sciences, 36(1), 43–48. https://doi.org/10.3906/vet-1102-791.

Wang, L., Guo, T. Z., Wei, T., Li, W. W., Shi, X., Clark, J. D., & Kingery, W. S. (2016). “Bisphosphonates Inhibit Pain, Bone Loss, and Inflammation in a Rat Tibia Fracture Model of Complex Regional Pain Syndrome”. Anesthesia and Analgesia, 123(4), 1033–1045. https://doi.org/10.1213/ANE.0000000000001518.

Rundle, C. H., Wang, H., Yu, H., Chadwick, R. B., Davis, E. I., Wergedal, J. E., Lau, K. H. W., Mohan, S., Ryaby, J. T., & Baylink, D. J. (2006). “Microarray analysis of gene expression during the inflammation and endochondral bone formation stages of rat femur fracture repair”. Bone, 38(4), 521–529. https://doi.org/10.1016/j.bone.2005.09.015.

Blaya, F., Pedro, P. S., Silva, J. L., D’Amato, R., Heras, E. S., & Juanes, J. A. (2018). “Design of an Orthopedic Product by Using Additive Manufacturing Technology: The Arm Splint”. Journal of Medical Systems, 42(3). https://doi.org/10.1007/s10916-018-0909-6.