Quality and Defect Prediction in Plastic Injection Molding using Machine Learning Algorithms based Gating Systems and Its Mathematical Models

Main Article Content

Abstract

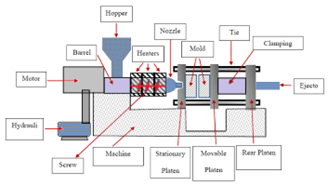

To achieve high quality products from Plastic Injection Molding (PIM) process it is very essential to identify the defective operations in automatic manner which is most challenging task. This paper proposes a Machine Learning (ML) approach to detect the complex faults occurrence during the PIM process. During initial sampling process of molding to achieve high quality and low time consumption it is essential to concentrate on the suitable determination of parameter values by considering the properties of injection molding process. For that purpose, a novel machine learning algorithms based gating system is introduced in PIM (MLGS-PIM). Technical evaluation can be done using simulation which combines the CATIA and MATLAB. Therefore in MLGS-PIM, a holistic approach is introduced to improve and predict the process quality of the parameters which is based on machine learning approaches. The considered machine learning approaches for this process are Artificial Neural Network (ANN) and Support Vector Machine (SVM). This two learning models are combined to achieve high quality under various conditions. Such novel ML based technique helps to increase the quality characteristics of the injection molding process and it is predicted with various parameter values where the simulation data and measurements are handled in an intelligent manner. The materials which are considered in the PIM process are thermoplastic polystyrene, thermoplastic acrylonitrile butadiene styrene and thermoplastic polyvinyl chloride where three types are gating systems are applied with it and consists of 3, 4 and 5 gates and as well the parameters which are measured for the output analysis are sum rate, bit error rate and convergence plot. The results show that the performance of the proposed MLGS-PIM approach significantly increases the performance when compared with the earlier approaches such as AntLion Optimization and PSO-MSQPA.

Article Details

References

Morgan, W.J. and Chu, H.Y., “Development of a Reliable Vibration Based Health Indicator for Monitoring the Lubricating Condition of the Toggle Clamping System of a Plastic Injection Molding Machine,” Applied Sciences, vol. 12, no.1, 2021, p.196, doi: 10.3390/app12010196

Ramorino, G., Agnelli, S. and Guindani, M., “Analysis of Reactive Injection Compression Molding by Numerical Simulations and Experiments,” Advances in Polymer Technology, vol. 2020, 2020, doi: 10.1155/2020/1421287

Dhutekar, P., Mehta, G., Modak, J., Shelare, S. and Belkhode, P.,”Establishment of mathematical model for minimization of human energy in a plastic moulding operation. Materials Today: Proceedings, 47, pp.4502-4507. Doi: /10.1016/j.matpr.2021.05.330

He, W., Yang, J., Chen, Y., Liu, P., Li, C., Xiong, M., Niu, X. and Li, X., “ Study on co-injection molding of poly (styrene-ethylene-butylene-styrene) and polypropylene: Simulation and experiment,” Polymer Testing, vol.108, no.1, 2022, p.107510,doi: 10.1016/j.polymertesting.2022.107510

Seleznev, M. and Roy-Mayhew, J.D., “Bi-metal composite material for plastic injection molding tooling applications via fused filament fabrication process,” Additive Manufacturing, vol.48, 2021, p.102375. doi: 10.1016/j.addma.2021.102375

Zhang, Y., Shan, S., Frumosu, F.D., Calaon, M., Yang, W., Liu, Y. and Hansen, H.N., “Automated vision-based inspection of mould and part quality in soft tooling injection moulding using imaging and deep learning,” CIRP Annals,vol.72, 2022, pp.429-439, doi: 1 0.1016/j.cirp.2022.04.022

Kvaktun, D., Hoffmann, A. and Schiffers, R., “Analysis of feature extraction algorithms for quality prediction using machine learning in injection molding,” Procedia CIRP, vol. 112, 2022, pp.590-595, doi: 10.1016/j.procir.2022.09.059

Finkeldey, F., Volke, J., Zarges, J.C., Heim, H.P. and Wiederkehr, P., “Learning quality characteristics for plastic injection molding processes using a combination of simulated and measured data. Journal of Manufacturing Processes, vol.60, 2020, pp.134-143, doi: 10.1016/j.jmapro.2020.10.028

Hopmann, C., Jeschke, S., Meisen, T., Thiele, T., Tercan, H., Liebenberg, M., Heinisch, J. and Theunissen, M., “Combined learning processes for injection moulding based on simulation and experimental data. In AIP conference proceedings, Vol. 2139, No. 1, 2019, p. 030003. AIP Publishing LLC.Doi: 10.1063/1.5121656

Obregon, J., Hong, J. and Jung, J.Y., “Rule-based explanations based on ensemble machine learning for detecting sink mark defects in the injection molding process,” Journal of Manufacturing Systems,vol. 60, 2021, pp.392-405.doi: 10.1016/j.jmsy.2021.07.001

Ke, K.C. and Huang, M.S., “Quality prediction for injection molding by using a multilayer perceptron neural network,” Polymers, vol.12, no.8, 2020, p.1812, doi: 10.3390/polym12081812

Jung, H., Jeon, J., Choi, D. and Park, J.Y., “Application of machine learning techniques in injection molding quality prediction: Implications on sustainable manufacturing industry”, Sustainability, vol. 13, no.8, 2021, p.4120, doi: 10.3390/su13084120

Ogorodnyk, O., Lyngstad, O.V., Larsen, M., Wang, K. and Martinsen, K., “ Application of machine learning methods for prediction of parts quality in thermoplastics injection molding,”In International workshop of advanced manufacturing and automation, 2021, pp. 237-244, doi: 10.1007/978-981-13-2375-1_30

Struchtrup, A.S., Kvaktun, D. and Schiffers, R., “Comparison of feature selection methods for machine learning based injection molding quality prediction,” In AIP Conference Proceedings, Vol. 2289, no. 1, 2020, p. 020052 , AIP Publishing LLC.Doi: 10.1063/5.0028546

Struchtrup, A.S., Kvaktun, D. and Schiffers, R., “Adaptive quality prediction in injection molding based on ensemble learning. Procedia CIRP, vol.99, 2022,pp.301-306, doi: 10.1016/j.procir.2021.03.045

Charest, M., Finn, R. and Dubay, R., “Integration of artificial intelligence in an injection molding process for on-line process parameter adjustment,” In 2018 annual ieee international systems conference (syscon) , 2018, pp. 1-6, doi: 978-1-5386-3664-0

Guo, F., Zhou, X., Liu, J., Zhang, Y., Li, D. and Zhou, H., “A reinforcement learning decision model for online process parameters optimization from offline data in injection molding,” Applied Soft Computing, vol. 85, 2019, p.105828, doi: 10.1016/j.asoc.2019.105828.

Park, H.S., Phuong, D.X. and Kumar, S., “AI based injection molding process for consistent product quality,” Procedia Manufacturing, vol. 28, 2019, pp.102-106, doi: 10.1016/j.promfg.2018.12.017

Tripathi, S., Mittermayr, C., Muhr, D. and Jodlbauer, H., “Large scale predictability analysis of process variables from injection molding machines,” Procedia Computer Science, vol.180, 2021, pp.545-560, doi: 10.1016/j.procs.2021.01.274

Gim, J. and Turng, L.S., “A review of current advancements in high surface quality injection molding: Measurement, influencing factors, prediction, and control,” Polymer Testing, 2022, p.107718, doi:1 0.1016/j.polymertesting.2022.107718