Comparative structural Analysis of Acme and Square thread Screw jack using Autodesk Inventor

Main Article Content

Abstract

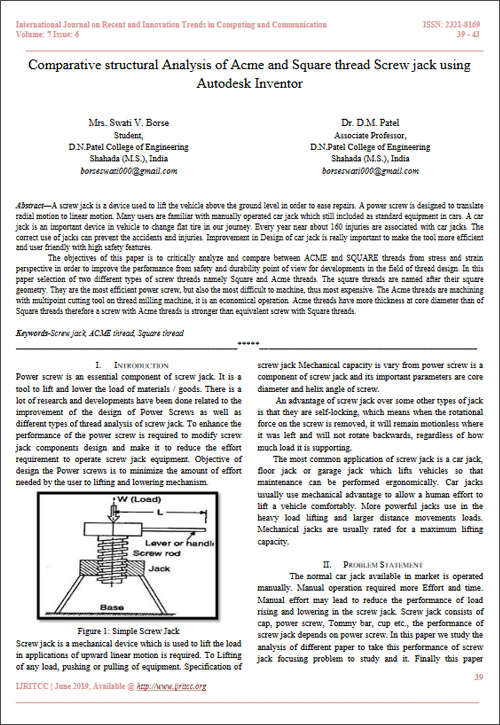

A screw jack is a device used to lift the vehicle above the ground level in order to ease repairs. A power screw is designed to translate radial motion to linear motion. Many users are familiar with manually operated car jack which still included as standard equipment in cars. A car jack is an important device in vehicle to change flat tire in our journey. Every year near about 160 injuries are associated with car jacks. The correct use of jacks can prevent the accidents and injuries. Improvement in Design of car jack is really important to make the tool more efficient and user friendly with high safety features.

The objectives of this paper is to critically analyze and compare between ACME and SQUARE threads from stress and strain perspective in order to improve the performance from safety and durability point of view for developments in the field of thread design. In this paper selection of two different types of screw threads namely Square and Acme threads. The square threads are named after their square geometry. They are the most efficient power screw, but also the most difficult to machine, thus most expensive. The Acme threads are machining with multipoint cutting tool on thread milling machine, it is an economical operation. Acme threads have more thickness at core diameter than of Square threads therefore a screw with Acme threads is stronger than equivalent screw with Square threads.